That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for Purpose of shearing machine,

metal shears,We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We invite you to visit our company for a personalized tour and advanced business guidance. The product will supply to all over the world, such as Europe, America, Australia,Hongkong, Marseille,Latvia, USA.We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success The application fields and use precautions of the shearing machineA Shearing machine is a machine that uses one blade to

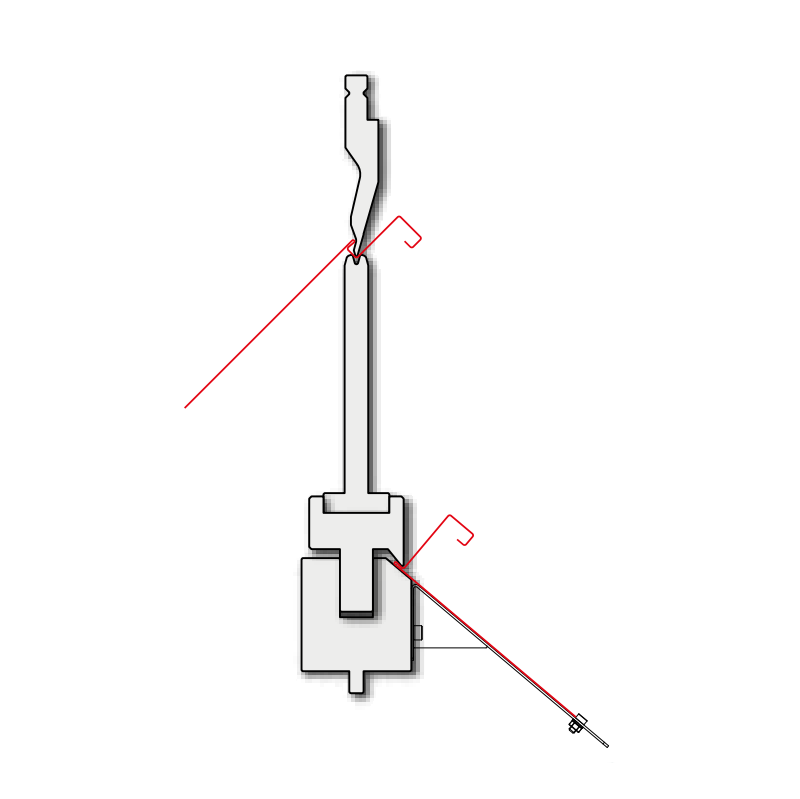

The press brake machine can meet the needs of various workpieces by replacing the mold of the press brake machine. Famil

CNC press bending machine is a kind of high precision and high-efficiency sheet metal bending processing equipment. It u

ZC-power mainly produces bending machines, shearing machines, punching machines and cutting tools, etc. It specializes i

The sheet metal bending process is not only directly related to the smooth progress of the company's production plan, bu

First, let’s see the definition of non-traditional machining.. Non-traditional machining, also known as “non-conventional machining” or “modern machining method”, generally refers to the machining method of removing or adding materials with energy of electricity, heat energy, light energy, electrochemical energy, chemical energy, sound energy and special mechanical …

The lighting system of a motor vehicle consists of lighting and signalling devices mounted or integrated at the front, rear, sides, and in some cases the top of a motor vehicle.They illuminate the roadway ahead for the driver and increase the vehicle's visibility, allowing other drivers and pedestrians to see its presence, position, size, and direction of travel, and its driver's intentions.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes.. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of …

The benefits of the hydraulic folding process include reduced risk and lessened surface damage to the workpiece when compared to what is created by the press brake method. Coining As the metal is squeezed between the halves of the die, the applied pressure deforms the workpiece and changes its thickness, forming it to the die design.