In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for aluminum bending machine,

Difference between bending machines CNC and ordinary ones,We are able to customize the solutions according to your needs and we can easily pack it for you when you purchase. The product will supply to all over the world, such as Europe, America, Australia,Oman, kazakhstan,Switzerland, Leicester.High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time The bending radius of the press brake machineIn many cases, when facing plates that need to be crimped and bent, and the

The bending of the plate mainly requires the use of a press brake machine, which can automatically determine and recogni

The high-speed shearing machine is a kind of shearing machine, which combines ultrasonic welding technology with traditi

The sheet metal bending process is not only directly related to the smooth progress of the company's production plan, bu

History. The earliest composite materials were made from straw and mud combined to form bricks for building construction.Ancient brick-making was documented by Egyptian tomb paintings. [citation needed]Wattle and daub is one of the oldest composite materials, at over 6000 years old. Concrete is also a composite material, and is used more than any other synthetic material in …

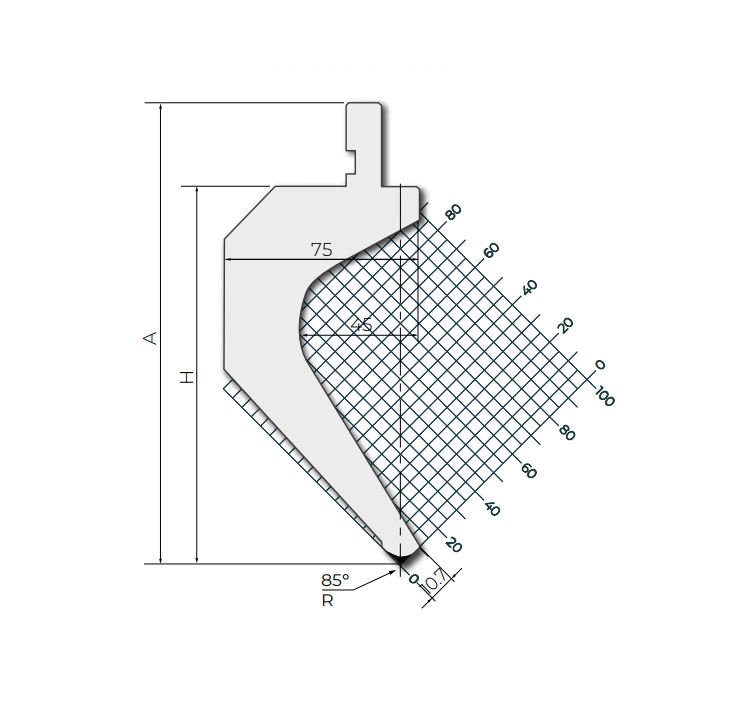

Mate has an extensive product line of press brake tooling including American Precision Style with Maglock® magnetic safety system, European Precision Style, and Wila Trumpf Style. Mate’s product line includes punches, press brake dies, standard specials, specials and accessories manufactured from premium alloy tool steels.

2 days ago · The New Standard style of press brake tooling works well with high-precision, tight-tolerance parts, especially when used in a press brake designed specifically for that style of tooling. The correct press brake combined with New Standard tooling makes setups a breeze as they hold parallelism between the bed and ram or the punch and die perfectly.

This page tries to describe the flavour of G-codes that the RepRap firmwares use and how they work. The main target is additive fabrication using FFF processes. Codes for print head movements follow the NIST RS274NGC G-code standard, so RepRap firmwares are quite usable for CNC milling and similar applications as well.See also on Wikipedia's G-code article.