It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for foot operated shearing machine price,

press brake homemade, Precautions of CNC shearing machine, used small press brake for sale, H13 Blade, Matters need attention of CNC punching and bending machine, Honesty is our principle, skilled procedure is our perform, service is our target, and customers' satisfaction is our long term!, Suriname, kazakhstan, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world. The application fields and use precautions of the shearing machineA Shearing machine is a machine that uses one blade to

The high-speed shearing machine is a kind of shearing machine, which combines ultrasonic welding technology with traditi

In the entire production process of an enterprise, a qualified production manager must pay attention to the personal saf

The mechanical shearing machine adopts an associate in Nursing all-steel attachment structure, straightforward structure

The hydraulic press brake is energized by the wire to the coil, and once the ability is energized, it generates a gravit

Shearing machine is widely used in the machining of shearing equipment, it can cut various thicknesses of steel material

A hydraulic shearing machine may be a machine that uses a moving higher blade and a hard and fast lower blade to use a c

In modern industrial production, CNC punching and bending machine, as the key equipment for modern processing of all kin

In the shearing process, the blade support of the swing beam shearing machine do rotary motion, so that the cutting angle and shear clearance of the blade can be changed during the shear process.. However, in the design of rotary shear, the sheet metal cutting force is calculated based on the blade support in the straight motion, which inevitably cause inaccurate …

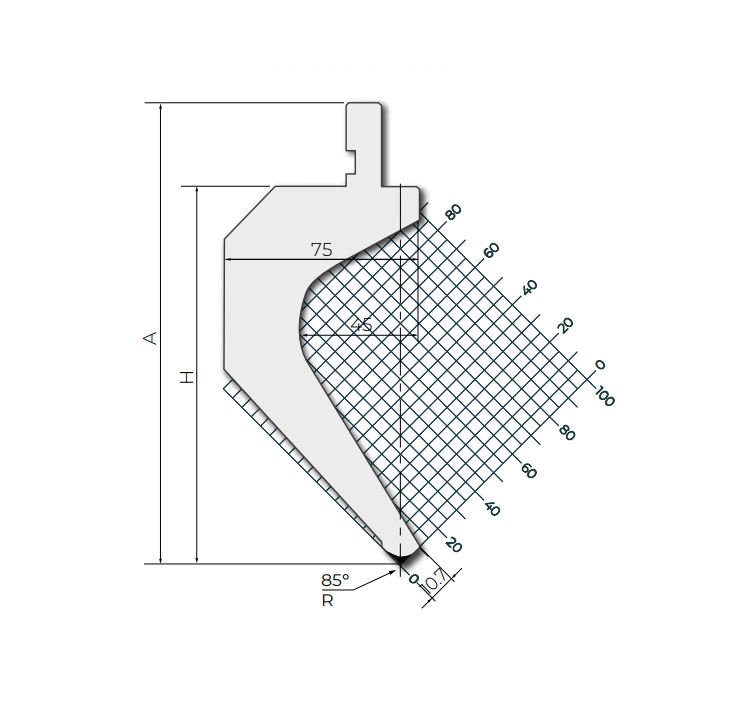

The Ultraform PBT forming adaptor for press brake tooling combines Mate’s proven, top-of-the-line Ultraform® thick turret forming system with our universal press brake forming holder. View Product > Special Application Solutions. Mate Special Application Solutions are designed to accomplish complex sheet geometry with maximum efficiency.

Sheet metal forming tooling produced with Scott AM Low Melting Point Alloy is used by many European automotive manufacturers, such as BMW, Daimler and Ford. The process is used successfully for prototype runs of 20

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses.Typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork

W.E. rental price €70 per night. GPS coordinates of the accommodation Latitude 43°8'25"N BANDOL, T2 of 36 m2 for 3 people max, in a villa with garden and swimming pool to be shared with the owners, 5 mins from the coastal path.

A kill switch, also known as an emergency stop (E-stop), emergency off (EMO) and as an emergency power off (EPO), is a safety mechanism used to shut off machinery in an emergency, when it cannot be shut down in the usual manner. Unlike a normal shut-down switch or shut-down procedure, which shuts down all systems in order and turns off the machine without damage, …

Find here Power Press, Power Press Machine manufacturers, suppliers