Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for usage of the press brake machine,

100t 4000mm press brake,Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us. The product will supply to all over the world, such as Europe, America, Australia,Algeria, Hongkong,Spain, Albania.Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions In the power industry, press brake machines are widely used. A press brake machine is a machine that can bend thin plate

The bending of the plate mainly requires the use of a press brake machine, which can automatically determine and recogni

The hydraulic press brake is energized by the wire to the coil, and once the ability is energized, it generates a gravit

How to use hydraulic guillotine shear machines A hydraulic shearing machine is a kind of machine which is separated by t

With the rapid development of industrial production enterprises in China, many small businesses are developing rapidly.

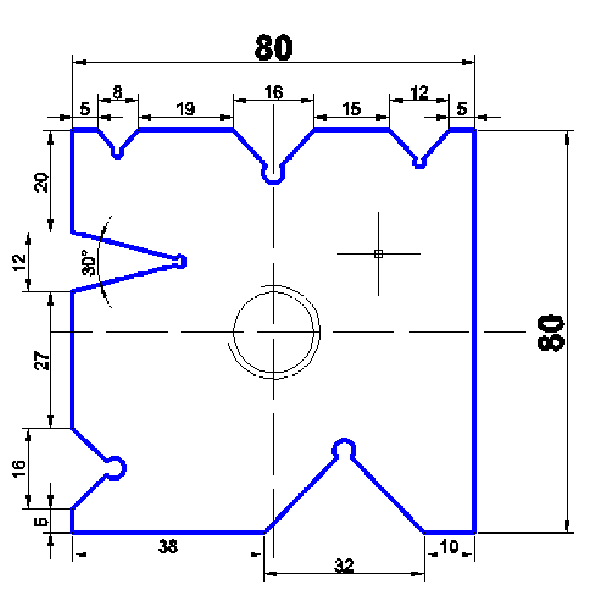

Press brake toolings including L-shape, R-shape, U-shape, Z-shape bending. Press brake upper die mainly include 90°punch, 88°punch, 45°punch, 30°punch, 20°punch, 15°punch, etc, while the lower die includes dual-V die and single-V die with various slot width from 4V to 18V.

Advantages of Hydraulic Shearing Machine. ... It is forbidden to cut excessively long and thick plate, not to shear the high-speed steel, tool steel and cast iron. The clutch should be off before starting, and the motor should not start with the load. Before starting, test the empty cutting, after everything works well, then start cutting ...

Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force.In this process, the piece removed, called the blank, is not scrap but rather the desired part.Blanking can be used to cutout parts in almost any 2D shape, but is most commonly used to cut workpieces with simple geometries that will be …

For general inquiries please call the KONE Customer Care Center at 877-276-8691. You can reach us 24 hours a day, seven days a week. For non-urgent service inquiries you may also e-mail the KONE Service Center at Americas.customer-support@kone.com.. For KONE eInvoice support please call 888-705-3612 or Billing.Questions@KONE.com.. Go to the contact form