Bending machines CNC is in the ordinary hydraulic bending machine with CNC operating system, is the upgrade of ordinary

A mechanical shearing machine is a kind of shearing machine. The mechanical shearing machine adopts a resistance key for

CNC press bending machine is a kind of high precision and high-efficiency sheet metal bending processing equipment. It u

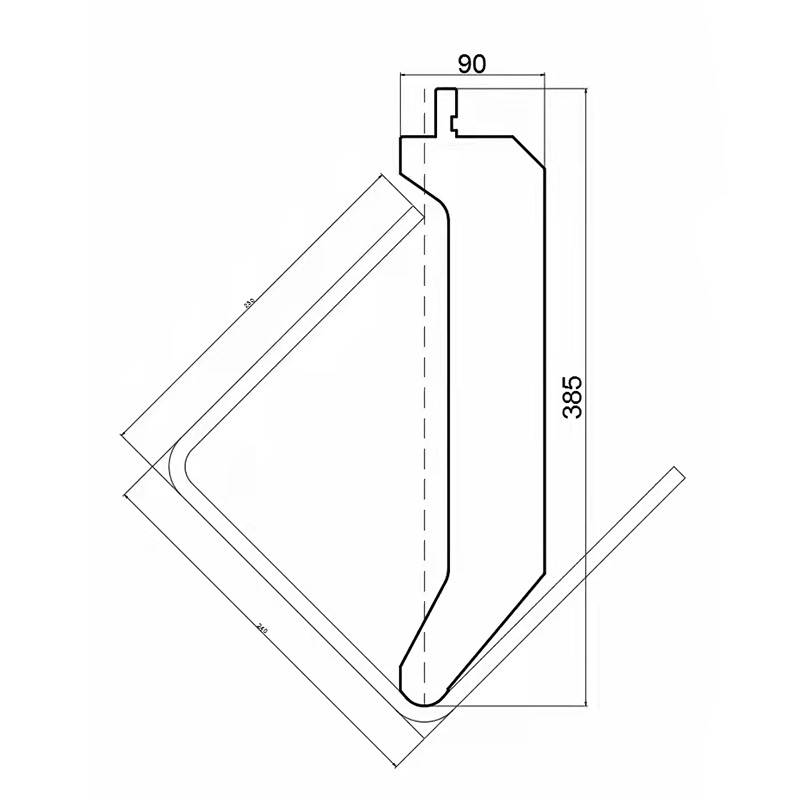

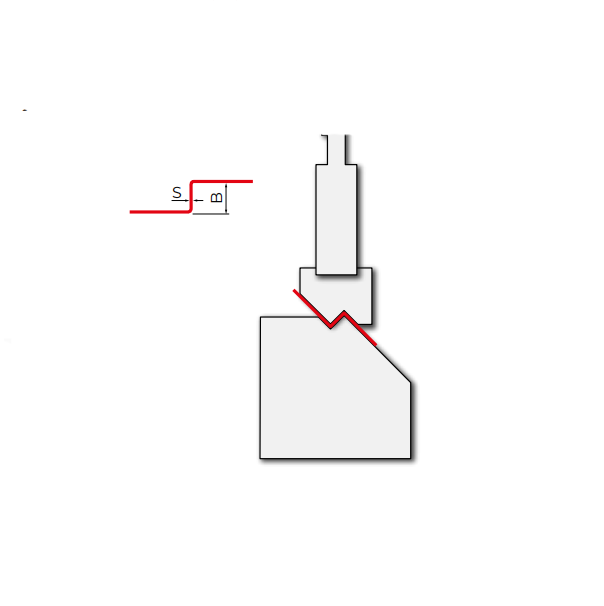

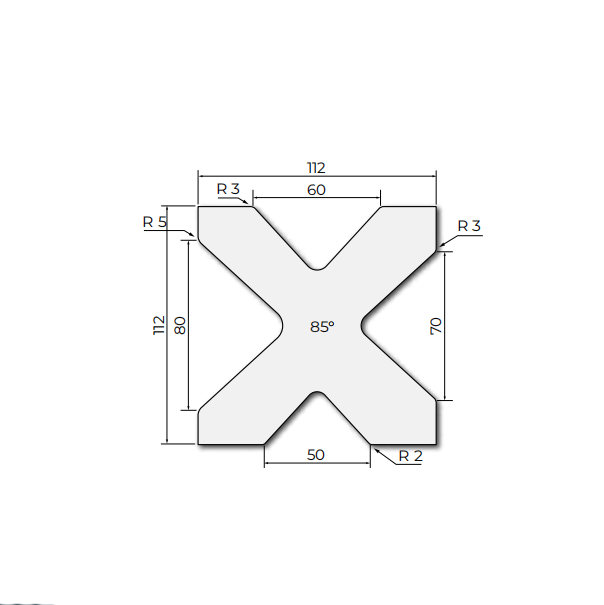

The press brake machine can meet the needs of various workpieces by replacing the mold of the press brake machine. Famil

A guillotine shear machine is a machine that uses one blade to shear the sheet in a reciprocating linear motion relative

The hydraulic press brake is energized by the wire to the coil, and once the ability is energized, it generates a gravit

An automatic CNC bending machine is an intelligent bending machine. Its comprehensive average efficiency is more than th

The sheet metal bending process is not only directly related to the smooth progress of the company's production plan, bu

Our ADS and AD-Servo press brakes are equipped with a fast and precise 2-axis CNC controlled back gauge. Optionally we offer a 4 Axis CNC back gauge (X-R-Z1-Z2) With this back gauge system the CNC press brake control calculates the depth, height and width of the back gauge fingers. This back gauge features superior accuracy and speed.

Bending. Wilson Tool leads the industry with precision, performance and innovation with a full line of European style, American Precision and WT Style Precision Press Brake Tooling. We manufacture state-of-the-art precision ground tooling so our customers can be the best fabricators in the world. Our innovative Nitrex? high endurance

Max Shear Width. 1000-2000 mm, 2000-3000 mm, 3000-4000 mm. "RAJESH GROUP" Brand Under Crank Shearing Machine is suited for cutting to size general purpose unalloyed steel. Structural steel sheets up to 4 mm thickness, with high productivity. Each machine, designed to the most accurate of efficiency, offers outstanding operational performance

TradeFord is a growing Manufacturer Directory and B2B Marketplace connecting Global Multi V Die Importers, Exporters, Suppliers, Traders and Manufacturers at a reliable, common platform. Take 1 Minute to Start Global Trade Now!

⑧ When bending hard or too thick product, do not use press brake die to bend steel bar or other cylinder products. ⑨ When using the press brake mold, the operators should have a clear mind. The upper die and lower die of press brake machine should be locked after alignment, in case the punch fall down to hurt the workers or damage the die.

Adjunct membership is for researchers employed by other institutions who collaborate with IDM Members to the extent that some of their own staff and/or postgraduate students may work within the IDM; for 3-year terms, which are renewable.

Introduction. This article covers all the information you need to know on hydraulic presses. ... process include reduced risk and lessened surface damage to the workpiece when compared to what is created by the press brake method. ... A hydraulic press is a mechanical device that uses the static pressure of a liquid, as defined by Pascal‘s ...

How to use the press brake. According to fabricate Q235 mild steel with hydraulic press brake to do a simple introduction: First, connect the power, turn on the key switch on the control panel, and then press the pump to start, then you can hear the oil pump rotating sound. (The machine does not run at the current time) Stroke adjustment.