With the rapid development of industrial production enterprises in China, many small businesses are developing rapidly.

The press brake machine can meet the needs of various workpieces by replacing the mold of the press brake machine. Famil

When the press brake machine is in use, the wire is energized to the coil, and after the power is energized, it generate

Press brake is suitable for large steel structure parts, iron towers, street light poles, high light poles, automobile b

ZC-power mainly produces bending machines, shearing machines, punching machines and cutting tools, etc. It specializes i

Shearing machine is widely used in the machining of shearing equipment, it can cut various thicknesses of steel material

In the entire production process of an enterprise, a qualified production manager must pay attention to the personal saf

The hydraulic press brake is energized by the wire to the coil, and once the ability is energized, it generates a gravit

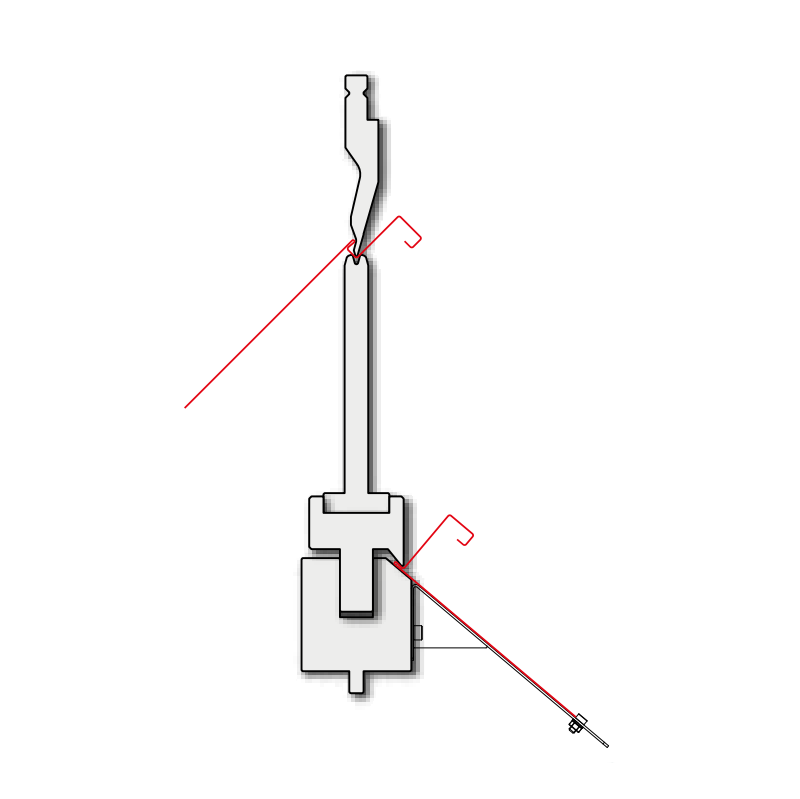

Introduction. The servo electric press brake is an equipment for processing thin plates. Its structure mainly includes a tool holder, worktable, a clamping feeding device and a CNC operating table. The worktable is composed of a base and a clamping piece feeding structure. The workpiece is positioned and clamped on the worktable and delivered

Enter the email address you signed up with and we'll email you a reset link.

Enter the email address you signed up with and we'll email you a reset link.

Our ADS and AD-Servo press brakes are equipped with a fast and precise 2-axis CNC controlled back gauge. Optionally we offer a 4 Axis CNC back gauge (X-R-Z1-Z2) With this back gauge system the CNC press brake control calculates the depth, height and width of the back gauge fingers. This back gauge features superior accuracy and speed.

86 574-8730 5555. 86 574-8730 2337. prosino@sinobaler. prosino-shredder. 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R.China

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die.Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working).For the latter two, the metal is …

Meanwhile, the upper roller continue to add downward pressure on the roller, the upper roller moves back and forth on the plate. When the plate pass the bottom of upper roller (the roller deformation zone) in turn, and stress exceeds the yield limit, it will produce plastic deformation, the plate obtained the plastic bending deformation along the full length, and processed into the …

Solar Air-Heating Panels 23 56 23 Removable Flood Barriers 10 71 19.16 Site Watering for Dust Control 01 57 26 Fiberglass Reinforced Protective Wall Covering 10 26 23.16 Variable Refrigerant Flow HVAC Systems 23 81 29 Artificial Rock Fabrications 32 39 33 Non-Destructive Concrete Examination 01 71 36 Concrete Staining 09 61 19 Tactile Signage ...