Shearing machine is widely used in the machining of shearing equipment, it can cut various thicknesses of steel material

The bending radius of the press brake machineIn many cases, when facing plates that need to be crimped and bent, and the

The CNC press brake is to uses the equipped mold to bend the cold metal sheet into various geometric cross-sectional sha

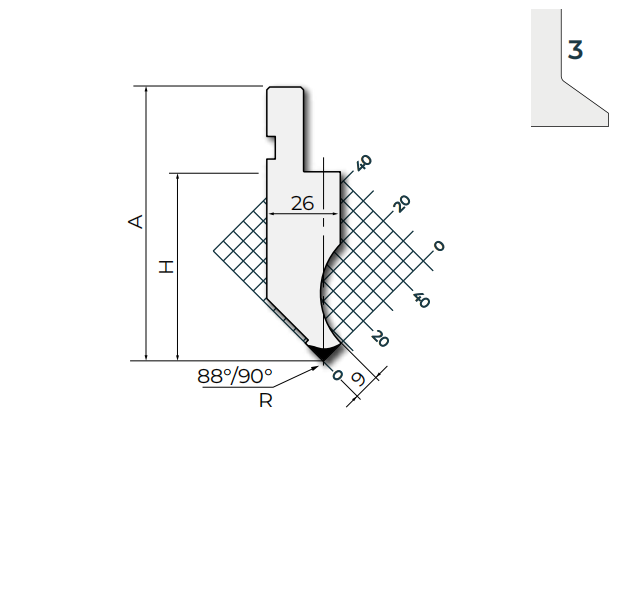

As we know, the press brake is a relatively large machine, so it will inevitably need some more important tools, these t

In modern industrial production, CNC punching and bending machine, as the key equipment for modern processing of all kin

The performance characteristics of the CNC shearing machine include CNC shearing machine forced positioning accuracy, wo

ZC-power mainly produces bending machines, shearing machines, punching machines and cutting tools, etc. It specializes i

The structure of the guillotine shear machine mainly includes a transmission system, slider (tool holder), bed (frame),

Hone cutting machine blades 12" Iqra Industrial Works. sona garden, Meerut plot no 10 near bijli bamba bypass fatehullahour, sona garden, Meerut - 250002, Dist. Meerut, Uttar Pradesh. TrustSEAL Verified. Company Video.

Standard Industrial Press Brakes

Woodward Fab: Your Metal Fabrication Partner Since 1966. Woodward Fab is a leading manufacturer and supplier of a wide variety of sheet metal fabrication tools. Our products are engineered to provide you with astounding results irrespective of your level of proficiency. With our tools, creating one-of-a-kind customized pieces is easy and ...

The hydraulic press brake is an industrial machine for bending and edging sheet metal workpieces. A bending punch presses the piece of sheet metal into a die, the profile of which creates an edge. This is why the press brake is also referred to as a die bending press, bending press, folding press or brake forming press. Bending machines with a ...

How Hydraulic Machines Work. Hydraulic machines use fluid to transmit force. From backyard log splitters to the huge machines you see on construction sites, hydraulic equipment is amazing in its strength and agility! On any construction site you see hydrauli

Before the shearing machine is reworked, starting oil pump to circulate the hydraulic oil for about an hour. 5. Hydraulic shearing machine maintenance procedures. In order to ensure the reliable operation of this shearing machine, the following procedures must be paid attention to. This procedure is graphically represented.

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver chuck. with hand-operated types dramatically decreasing in popularity and cordless battery-powered ones proliferating.. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects.

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing.Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet. The punch often passes through the work into a die.A scrap slug from the hole is …