It is the employees of our company who are fully committed to our customers and continuously strive to improve manufacturing processes, customer service, and product offerings as a way to ensure their satisfaction. container making machine,

press brake turkey, Manual folding machine, Precautions of CNC shearing machine, NC Hydraulic Press Brake, Introduction of the hydraulic press brake, Adhering to the business philosophy of 'customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us give you best service!, Sao Paulo, Zurich, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you. For the production management personnel of the enterprise, during the entire production process, not only should pay att

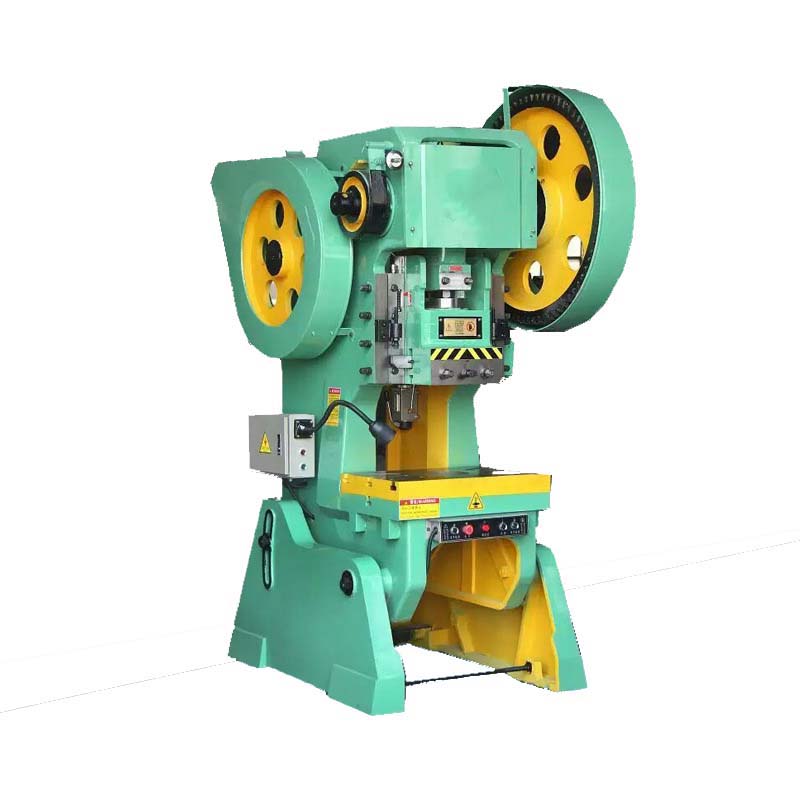

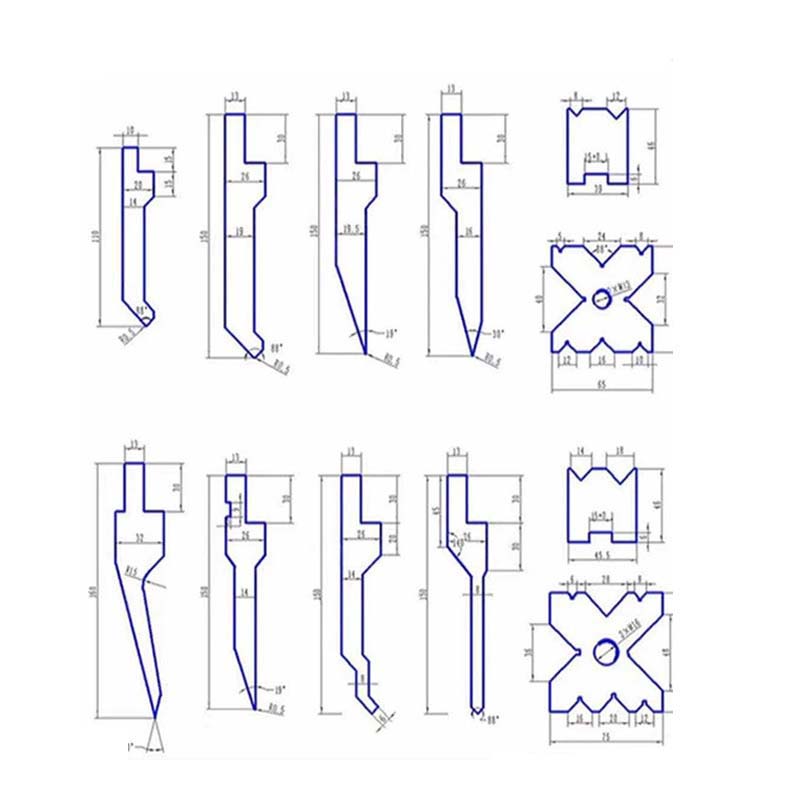

ZC-power mainly produces bending machines, shearing machines, punching machines and cutting tools, etc. It specializes i

The hydraulic press brake is energized by the wire to the coil, and once the ability is energized, it generates a gravit

CNC shearing machine generally adopts general-purpose or special-purpose computer to realize digital program control, wh

A hydraulic shearing machine may be a machine that uses a moving higher blade and a hard and fast lower blade to use a c

In the power industry, press brake machines are widely used. A press brake machine is a machine that can bend thin plate

The sheet metal bending process is not only directly related to the smooth progress of the company's production plan, bu

How to use hydraulic guillotine shear machines A hydraulic shearing machine is a kind of machine which is separated by t

Also, hydraulic shears are best if the operation requires intense pressure. They don’t require a lot of maintenance, will operate continuously, and are fast and quiet. ... As the upper knife is forced downward, it cuts the metal into two parts. Straight-knife shearing is the most economical method of cutting straight-sided blanks from flat ...

Advanced Power Electronics and Electric Machines Facilities. NREL's advanced power electronics and electric machines experimentation facilities feature a range of equipment and enable world-class experimental and modeling capabilities. This press can apply forces up to 30 tons (~300,000 nano) when synthesizing bonded interfaces.

Hydraulic shearing machine is a kind of machine that uses the moving upper blade and fixed lower blade to apply shear force to metal plates of various ... and strictly follow the safety technology and operating procedures. ... Need to find who can give us price and availability on a Heavy Duty Hydraulic Shear Machine Guillotine Style. Reply ...

Ref. no. Description Upper blade teeth Lower blade teeth Shearing type PU; 18534: Lower blade: 20: Cattle Shearing, very dirty animals: 1/50: 18978: Upper blade

With the aim to best satisfy every application requirement, Faccin produces and sells various types of plate bending machines. The range includes three models suitable for bending thin plates: ... Nowadays, plate bending has become more and more a CNC-supported operation. Faccin was the first manufacturer to use CNC on four roll-plate bending ...

In addition, the blade must also have good high temperature resistance. The knife edge cannot be annealed due to high temperature, otherwise the life will be drasti

Carbon steel plate thickness< 12mm, use the shearing machine for blanking as far as possible (otherwise, use semi-automatic cutting), after cutting process, clean the slag, and deburring. When the groove is needed, the plate thickness > 6mm shall be carried out by semi-automatic cutting machine or rolling chamfering machine;

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations.Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine.